Kyabram Refrigeration is an authorised agent of GEA (Westfalia) and Packo Milk Vats. We have been installing, maintaining and building refrigeration systems for over 40 years. We carry an extensive range of spare parts for all brands of milk vats.

Once chilled, milk must be chilled rapidly and stored correctly. Milk vat refrigeration must be efficient and effective. Both brands of Milk vats exceed these expectations.

These high-efficiency milk vat storing and cooling systems are fast cooling resulting in a better milk product translating to better money in farmer’s pockets.

Today, it is all about achieving more, resulting in bigger farms, longer milking times, and higher production a rapid cooling method is paramount to a farmer’s success.

Please call us to discuss your needs as we have the correct solution that is customized to your production needs.

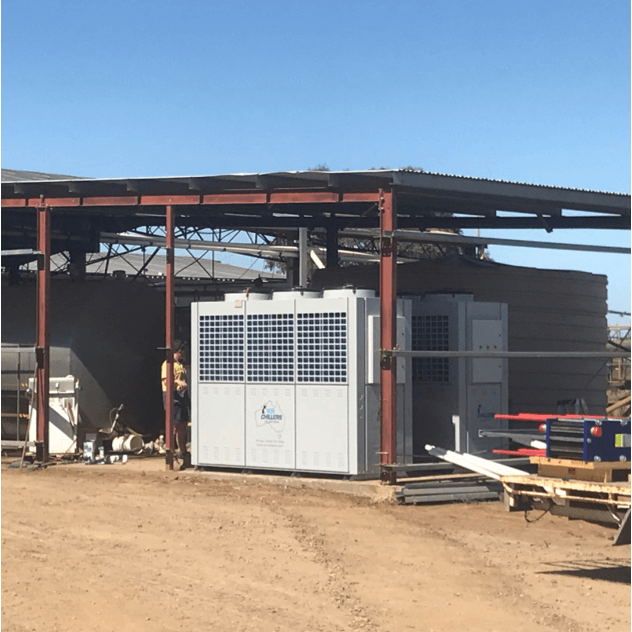

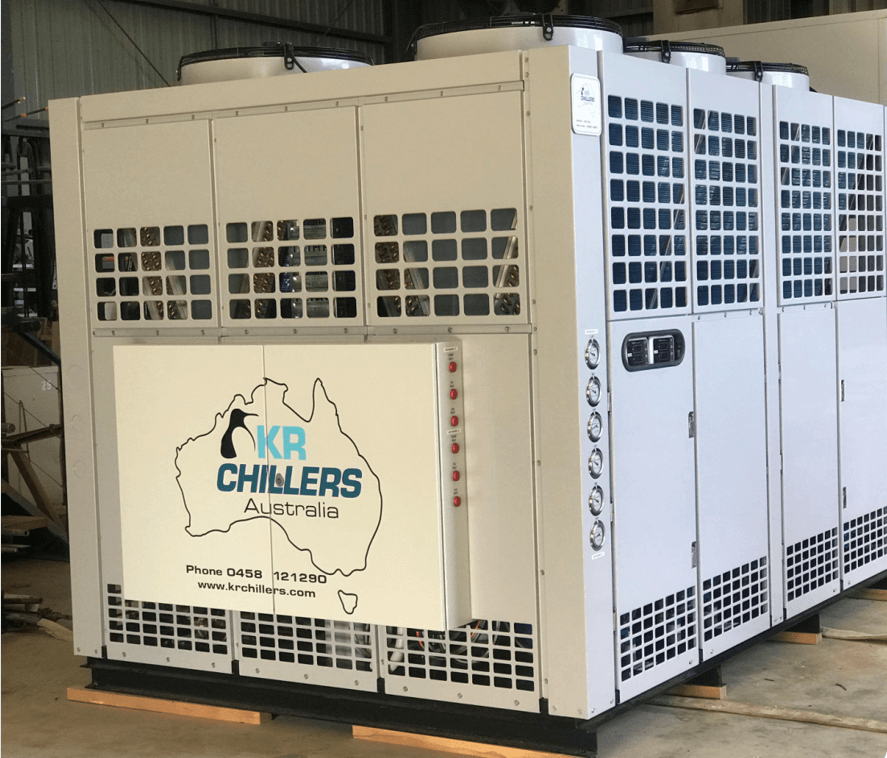

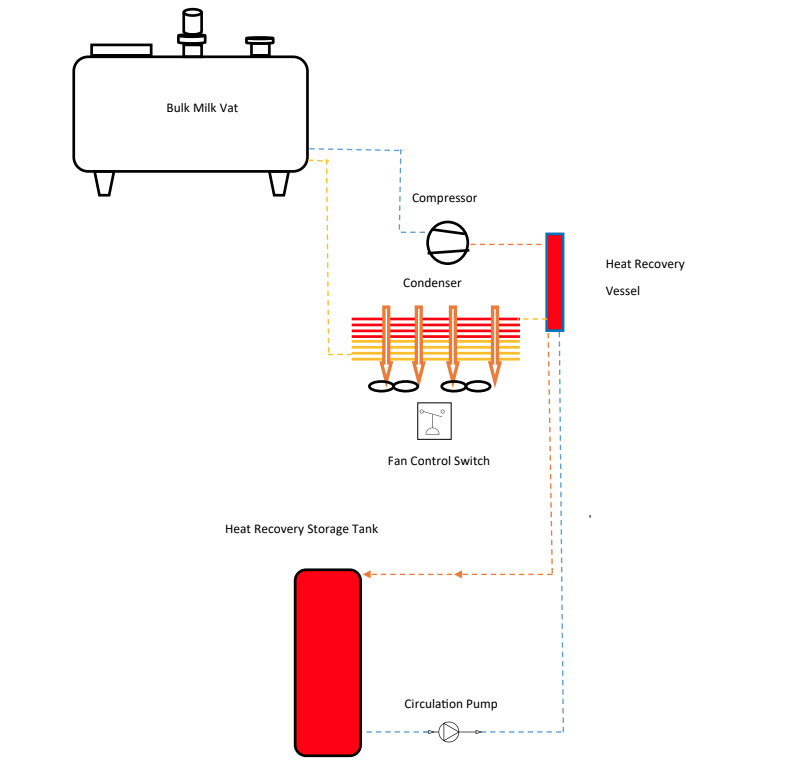

We are the one-stop shop for all your rapid cooling needs – Industrial Chillers, Plate Coolers, Glycol Chillers and Milk Vats. We also specialize in dairy efficiencies with the add-on of Heat Recovery Units creating your own Hot Water.

PACKO- “I CONTROL / STANDARD”

The future is already here today, it is called- “I Control”.

Farmer / Tanker Driver- Interface, Touch Screen, Cooling & Washing Control System

Traceability, accountability and information at your fingertips, these are the needs of the modern day dairy farmer. A highly technically advanced package the first basic requirement, secondly this package must be robust, simple and able to withstand the rigors and abuse a working farm dishes out each and every day.

Thirdly and paramount to all, this advanced package must come with total ease of use. Simple and un complicated, able to be used simply by a child, Packo presents to the modern day dairy farmer its latest advancement the-.

I Control

A touch screen milk tank, washing & cooling operating system, integrated with all hardware to wash and cool the milk vessel. In a world of touch screen technology Packo has meet the demands and questions from farmer’s world-wide. Multiple packages, components and future expansion on farm, compressed into a simple but highly advanced unit. The future in milk cooling is here, it is called- “I Control”

First milk cooling tank with a 7” touch screen ! – All information is 1 touch away

- Easy to use high resolution 7” touch screen display

- Detailed analysis of logging information, set parameters, cooling, cleaning and agitation

- Data files / logs are converted into viewable graphs

- Easy interchange of data. Each milk cooling tank has its own ID installed on one SD card enabling quick and fast adjusting of parameters

- Upgradable for robotic milking with pneumatic valving & PC communication module

- Option of liquid volume indicator (PACAP)

Safeguarding the milk quality is the key topic !

COOLING :

- No human interface required, automatic startup of the cooling after cleaning (Robotic Usage)

- Milk quality preserved, thanks to the built in back up features such as a secondary milk temperature safety probe.

CLEANING :

- Optimal water consumption thanks to the individual setting of water volume per cleaning step

- Automatic adjustment of cleaning times according to the type and volume of the tank and the chosen amount of cleaning water.

- Individual ability to change cleaning step times including sequence. Ability to change individual dosage pumps for all chemicals used Acid, Detergent and Sanitizer.

I Control” / Wash System

All “I-Control” / Standard control systems come complete with all equipment / hardware to wash the milk cooling tank upon emptying.

Fitted as standard is a powerful and effective 1.5 Kw Packo built wash pump. Incorporating Packo’s patented “Rotojet” Sprayball system, hygienic cleaning of the vessel is assured. Dosage pumps dispensing acid, detergent and sanitiser alternating each separate wash takes the worry out of having to change chemicals each time.

Smart features inbuilt even alert the farmer if the wash water is too low in temperature, in this event quick action will safe guard milk quality before problems occur. This is only but one intelligent feature of many contained within the I Control.

Effective cooling alone is means nothing if the cleaning system is the weak link. Packo’s years of research and development in the field of cleaning systems has given them a second to none reputation. The new “I Control” continues this proud tradition and again raises the bar in the important field of tank hygiene.

Available Options for “i control / standard

- ECO-Wash / Time saving wash system / water storage rear cylinder

- GSM / Mobile & PC communication module

- Robotic pneumatic valving for robotic milking applications

- Digital – Liquid level indicator / dipstick- “PACAP”

Gea Milk Vats – Intelligent Cooling Systems

The key characteristics of the milk tank at a glance:

- The milk tank is available in 24 variants: a large selection for customized milk cooling

- Milk tank with top-quality insulation

- Individually configured milk intake: With inlet from above, from below, front the front and from the back

- Long-lasting evaporators: high reliability of milk storage thanks to constant quality control.

The efficiency with which you are able to cool and store the milk becomes obvious when you look at the statistics. The TCool milk tank prevents the formation of thermal bridges and limits the temperature increase to 0.5°C in a period of 12 hours.

Storing milk: excellent cleaning for milk production

Regardless of which tank you decide on complete drainage at the end of the cleaning process is possible with a vertical high-performance pump to prevent the milk from freezing which could impair the milk quality. An intake filter on the pump prevents the spray head from clogging and additionally protects the pump.

The general dosage of the cleaning agent is carried out using the pump. This prevents direct contact with the cleaning agents and offers the additional advantage of precisely regulated quantities. The ICool control system handles changes to the cleaning agent, which saves you time and prevents contact with powerful cleaning agents which could be hazardous to your health. When storing and cooling milk several forms of contamination can occur, making the use of various cleaning processes necessary.

Choose between alkaline and acidic cleaners. If desired, disinfection using a third pump is also possible.

Storing and cooling milk: as individual as never before with the GEA milk tank.

You can cool your milk with the TCool milk tank using a total of 24 different variants and capacities – from 1,010 up to 33,500 litres. The advantages:

- Cooling milk: You save energy with the milk tank

- The tank can be efficiently cleaned

- Easy to operate ICool control system

Monitor and control every parameter with the ICool control system. This milk control system enables you to achieve an accuracy level of +/- 0.2 % at 4 °C. The ICool control system can also monitor your energy consumption fully automatically, alerting you to any errors that may occur in the cold chain.

Cool and store milk, and store the most important data

Get the most out of your ICool control system with ICool Analyzer. Your benefits: ICool Analyzer gives you easy access to status information for up to 4 cooling units and the agitation process. The software also now provides an option to record comprehensive volume and temperature profile information. With ICool Analyzer, you can access the last 100 washing cycles directly from the display, and archive up to 10 years’ worth of data onto a USB stick. The data can also be exported as a CSV file for further analysis in Excel.